EMS

CTU vs. EMS Calibration: Why Calibrating Both Is Critical for Compliance and Operational Clarity

Apr 23, 2025

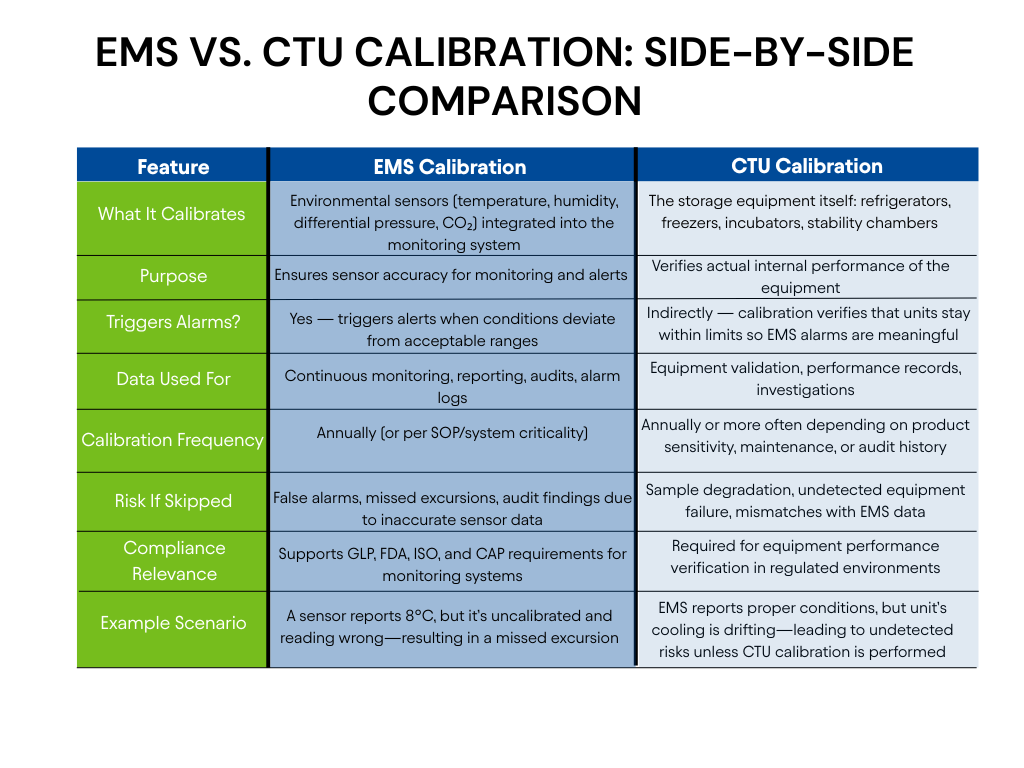

In highly regulated lab environments, CTU and EMS calibration are essential to ensure monitoring, audit readiness, and uninterrupted operations. Yet confusion still exists around the differences between Environmental Monitoring System (EMS) calibration and Controlled Temperature Unit (CTU) calibration, and more importantly, why calibrating both is essential.

If you’re a Lab Manager, Quality Manager, or responsible for Operations, understanding the distinction—and the connection—between EMS and CTU calibration could save you from unnecessary investigations, reduce the likelihood of deviations, and strengthen your overall Good Laboratory Practice (GLP) framework.

Let’s break it down from both a compliance and day-to-day operations perspective.

EMS Calibration: Ensuring Sensor Accuracy

What is it?

EMS calibration focuses on the sensors integrated into your monitoring system, including temperature, humidity, differential pressure, and CO₂. These sensors are responsible for capturing real-time environmental data and triggering alerts when conditions fall outside set parameters.

Why it's critical:

EMS sensors are used to generate logs, trigger alarms, and support investigations. If the sensor is out of calibration, you risk basing decisions—and compliance documentation—on inaccurate data. This can result in false alarms, missed excursions, or audit findings due to discrepancies in reported values versus actual environmental conditions.

When is it done?

Typically, EMS calibration is performed annually during a scheduled service visit. However, frequency may vary depending on internal SOPs, system criticality, and regulatory expectations.

Operational & Compliance Impact:

For operations and quality teams, an uncalibrated EMS sensor can trigger misleading alarms or fail to detect real issues, consuming staff time and prompting unnecessary investigations. From a compliance standpoint, inaccurate EMS data increases the risk of observations, data integrity concerns, and findings during inspections.

CTU Calibration: Validating Equipment Performance

What is it?

CTU calibration focuses on the equipment responsible for storing your critical inventory—refrigerators, freezers, incubators, and stability chambers. During this process, a NIST-traceable calibrated reference standard is used to verify that the internal conditions of the unit are within expected tolerances.

Why it's critical:

Even with a perfectly calibrated EMS sensor, if the CTU itself is out of specification, the integrity of your samples or products is still at risk. Relying on one data point alone can be misleading, particularly if an EMS sensor is functioning properly while the CTU cooling system begins to drift. Dual calibration ensures alignment between what the monitoring system reports and what the unit is actually doing.

When is it done?

CTU calibration is commonly done annually, but some organizations increase the frequency based on product sensitivity, audit history, or regulatory environment. It's also advisable to recalibrate CTUs after major maintenance, relocation, or system anomalies.

Operational & Compliance Impact:

For Lab Managers and Quality professionals, CTU calibration reduces the risk of deviation by validating the equipment’s true performance. Without it, discrepancies between EMS data and CTU performance can lead to investigations, added documentation, or even product loss. Calibrating the CTU closes this gap.

Need help aligning your CTU and EMS calibration plans? Request an assessment from a compliance specialist!

Why Calibrating Both EMS and CTUs Matters: A Dual-Data Approach

Calibrating both the EMS and the CTU provides a redundant, traceable record of environmental performance — offering two validated data points for every monitored condition.

Real-World Example:

If an alarm is triggered on the EMS, but the CTU isn’t calibrated (or vice versa), teams are left scrambling to determine which reading is correct. This can result in:

- Unnecessary deviation reports

- Delayed responses to real issues

- Uncertainty in root cause investigations

- Potential observations or findings during audits

When both CTU and EMS systems are calibrated, you eliminate ambiguity. Your logbooks align, your audit trail is clean, and your team can respond with clarity and confidence.

GLP and Daily Operations: The Manager’s Perspective

From the Lab Manager’s point of view, calibrated systems reduce interruptions and uncertainty. When a unit alarm sounds, having confidence in both the EMS and the CTU data avoids excessive troubleshooting and keeps workflows running smoothly.

From the Quality Manager’s perspective, dual calibration supports GLP principles by:

- Ensuring data integrity

- Reducing deviation risk

- Providing validated evidence in investigations

- Supporting smooth, defensible audits

From an Operations standpoint, calibrated systems mean fewer escalations, fewer surprises, and more efficient use of staff resources. Teams can act quickly and accurately because they trust the data.

Questions You Might Be Asking

Whether you manage a lab, oversee quality systems, or handle operational compliance, these are some of the most common questions that come up when discussing EMS vs. CTU calibration:

1. Do I really need both EMS and CTU calibration?

Yes — particularly in regulated, GxP, or audit-sensitive environments. EMS calibration ensures that your monitoring system is reporting accurate data, while CTU calibration verifies that the storage unit is maintaining proper conditions. Together, they create a cross-validated record that supports compliance, minimizes risk, and improves audit defensibility.

2. My EMS sensors are calibrated — isn’t that enough?

Not necessarily. A calibrated EMS sensor could still report that a fridge is 9°C if the fridge is actually malfunctioning, and the sensor is doing its job. CTU calibration would have identified the equipment issue before it became a risk, giving you an extra layer of protection and helping prevent a deviation from occurring in the first place.

3. Does CTU calibration require downtime?

In most cases, CTU calibration is non-invasive and minimally disruptive. It can often be performed without removing inventory, depending on your SOPs, unit design, and risk tolerance. We work closely with your team to minimize workflow interruptions while ensuring calibration integrity.

4. Are CTU calibrations required by the FDA, CAP, or ISO?

While regulatory language may vary, routine calibration of storage and testing equipment is widely expected across FDA-regulated, CAP-accredited, and ISO-certified facilities. Proper calibration supports GLP principles, traceability, and audit-readiness—and helps avoid findings during inspections.

5. Can Rees Scientific perform both EMS and CTU calibrations?

Yes. Rees Scientific provides both services, along with environmental mapping, validation, and preventative maintenance. We can also bundle calibration visits to streamline scheduling, reduce downtime, and support a unified compliance strategy.

Final Thoughts: Eliminate Deviation Before It Starts

Dual calibration isn’t just about ticking regulatory boxes—it’s a proactive strategy that supports compliance, operational excellence, and cost avoidance. It eliminates confusion, strengthens your data trail, and reduces the risk of observations during audits.

In short, when both your EMS and CTU are calibrated, you remove the guesswork. You reduce the noise. And most importantly, you eliminate deviation before it starts.

Let’s help you build a dual-calibration plan that supports your operational goals, satisfies regulatory requirements, and keeps your systems audit-ready. Request and Assessment today!