EMS

Building Automation Systems vs. Environmental Monitoring Systems: Understanding the Difference and Why It Matters

Author: Kristie Naulty

Jul 24, 2025

Controlling the environment of regulated and research-intensive spaces such as labs, hospitals, cleanrooms, pharmaceutical and biotech manufacturing facilities is critical to ensuring product integrity, patient safety, and regulatory compliance.

This is where two systems come into play: the Building Automation System (BAS) and the Environmental Monitoring System (EMS). While they may appear similar, both handle environmental data, but their roles, capabilities, and importance in regulated environments are significantly different.

Understanding where one ends and the other begins can help your team avoid costly oversights and build a more resilient, audit-ready operation.

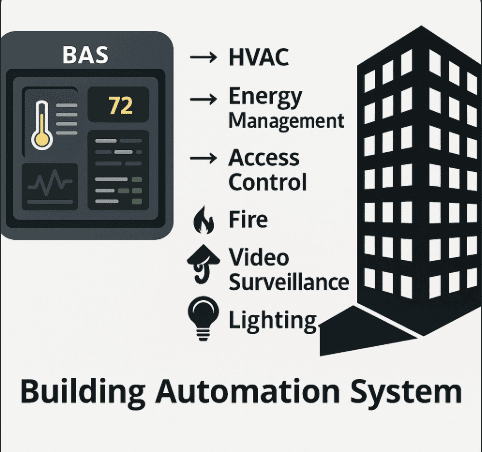

What Is a Building Automation System (BAS)?

A BAS is designed to control and optimize facility infrastructure. It manages systems like:

- HVAC (heating, ventilation, air conditioning)

- Lighting

- Door access and building security

- Fire alarms and suppression systems

- Elevators and energy usage

These systems improve comfort, reduce energy consumption, and support day-to-day operations. Facility and engineering teams rely on the BAS to ensure the building runs efficiently and safely.

What Is an Environmental Monitoring System (EMS)?

An EMS monitors critical environmental conditions tied to product quality, research integrity, and regulatory compliance. It doesn’t control building systems; it observes, documents, and alerts when something deviates from defined parameters.

A purpose-built EMS provides:

- Continuous monitoring of temperature, humidity, differential pressure, CO₂, etc.

- Real-time alerts via text, email, or phone when conditions fall out of range

- Secure, audit-ready data logging and historical trends

- Validation under 21 CFR Part 11, EU Annex 11, GxP, CAP, CLIA, and ISO

- Support for calibration, mapping, and requalification services

In short, the EMS protects what the BAS cannot: your products, your data, and your compliance status.

Why Some Teams Extend BAS for Monitoring and Where the Challenges Begin

On paper, using the BAS for environmental monitoring seems efficient. It offers one system to manage, fewer devices to install, and the potential for upfront cost savings. But in regulated environments, this approach can sometimes overlook the specific needs of validated environments. In GxP settings, having an inadequate system can directly impact data integrity and audit readiness.

1. “We already paid for the BAS, why not use it for monitoring too?”

During construction or renovation, teams often bundle BAS installation with other controls. Adding sensors to monitor cleanrooms or refrigerators can seem like a cost-effective shortcut.

In practice: these add-ons are often not calibrated or validated to the standards required for audit readiness.

2. “Let’s centralize everything, it’ll be easier for IT.”

Consolidating systems may sound like a clean solution, especially for IT teams tasked with system oversight and security.

However: most BAS platforms don’t offer validated audit trails, secure user access control, or regulatory-grade reporting. Retrofitting these features can be complex and may still fall short of compliance expectations in regulated settings.

3. “We’re trying to keep costs down.”

Using existing infrastructure for more functionality feels like a smart financial move, especially in budget-conscious projects.

But the hidden costs can add up quickly. Facilities that try to make the BAS do both jobs often end up paying more for patchwork solutions, manual data extractions, failed audits, or requalification work.

Why Separation Matters: Critical vs. Non-Critical Systems

The single biggest reason to separate EMS from BAS comes down to risk management. An EMS is a critical, validated system. A BAS is a non-critical, typically non-validated system. When the two are linked too closely, a problem with one can disrupt the other.

For example:

If your BAS controls the HVAC fan supplying air to a space, and it’s also monitoring a critical refrigerator in that space, what happens if the BAS fails? A fan issue could take the BAS offline and now your monitoring system is down, too. You’ve lost visibility into the condition of the refrigerator and its contents.

This is why the EMS must remain independent. It must continue functioning and alarming, no matter what’s happening on the building systems side.

While a BAS can monitor a refrigerator, that functionality often lacks the controls and validations required for regulated use. Critical assets, sensitive samples, and compliance requirements demand a system that’s dedicated, validated, and isolated from facility-level disruptions.

BAS vs. EMS in GxP-Regulated Environments: A Side-by-Side Look

In environments governed by FDA, EMA, ISO, or other global standards, the distinction between BAS and EMS is not just operational; it’s regulatory.

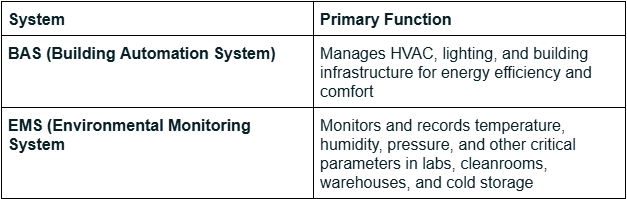

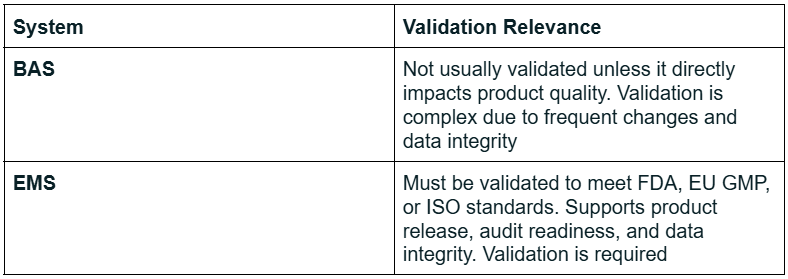

1. Purpose and Role

2. Validation Expectations

3. Key Regulatory Considerations

- Data Integrity: EMS systems retain data with secure audit trails. BAS platforms typically lack the security and traceability needed for compliance documentation.

- Alarm Management: EMS alerts in real time and logs all alarm events and responses, critical for audit defense and CAPAs.

- User Access Controls: EMS systems support user-level authentication, electronic signatures, and role-based access, in line with 21 CFR Part 11 and Annex 11. BAS systems typically do not.

4. Which Should Be Validated?

Bringing It Together: Separate, But Capable of Communicating

Your BAS and EMS don’t need to operate in complete isolation. With BACnet or Modbus compatibility, a properly designed EMS can exchange data with your BAS for centralized dashboards, analytics, or facility-wide reporting.

But integration should not mean dependency. A validated monitoring system should remain operational and independent, even if the BAS goes down. That’s the kind of resilience regulated environments require.

Your Environment, Your Decision

No two facilities are exactly the same. Some teams want standalone EMS systems for maximum protection. Others prefer systems that can share data when it’s useful. The key is to choose a setup that supports your compliance needs, risk tolerance, and operational priorities.

At Rees Scientific, we support both approaches. Whether you want to keep your EMS fully separate, integrate with your BAS, or somewhere in between, we’re here to guide you through it. Our team will help you make informed choices that protect your environment and keep your systems audit-ready at all times.