Particle Counter Sensors

Real-time airborne particle monitoring for controlled environments.

Airborne particle monitoring plays a critical role in maintaining cleanroom performance, protecting sensitive processes, and supporting environmental control strategies across pharmaceutical, biotech, and advanced research environments. Particle counters provide continuous visibility into particle levels, helping teams quickly detect changes that could impact operations.

Rees Scientific offers a range of airborne particle counters designed to support everything from localized monitoring to high-flow cleanroom applications.

Regulatory Alignment

Particle counters are commonly used to support compliance with global cleanroom and aseptic processing requirements, including:

- ISO 14644-1 and 14644-2 for cleanroom classification and monitoring

- EU GMP Annex 1 guidance for sterile manufacturing environments

- FDA GMP expectations for environmental monitoring programs

- USP <797> and <800> requirements for sterile and hazardous drug compounding

When properly selected, installed, and maintained, particle counters help demonstrate that controlled environments are operating within defined limits and validated classifications.

Typical Applications by Industry

Whether monitoring a single location or integrating into a facility-wide monitoring system, particle counters provide the data needed to understand environmental conditions in real time. Particle counters are commonly used in:

Cleanrooms and classified spaces

Pharmaceutical and biotech manufacturing

Cell and gene therapy environments

Compounding pharmacies

Research laboratories

Isolators, RABS, and biosafety cabinets

HVAC and room-level monitoring

Particle Counter Options

Low-Flow Airborne Particle Counters

Low-flow particle counters are ideal for continuous monitoring at fixed locations where space is limited and airflow disruption must be minimized.

Key characteristics:

- Particle size sensitivity down to 0.3 µm or 0.5 µm

- Low sample flow rates for localized monitoring

- Side or downward exhaust options

- Available with or without integrated flow sensing

Typical use cases:

- Cleanrooms and gowning areas

- Pass-throughs and buffer rooms

- Equipment enclosures and cabinets

1 CFM Airborne Particle Counters

1 CFM particle counters are commonly used in regulated environments where higher sample volumes are required to better represent room conditions.

Key characteristics:

- 1 CFM sample flow

- 0.3 µm or 0.5 µm particle size detection

- Multiple exhaust configurations

- Designed for continuous, fixed-location monitoring

Typical use cases:

- Classified cleanrooms

- Critical processing areas

- Fill/finish environments

- Controlled production spaces

Remote Particle Counters With Pump

Remote particle counters with an integrated pump are designed for continuous monitoring where you want a self-contained device at each sample point, without relying on a centralized vacuum system.

Key characteristics:

- Built-in pump reduces installation complexity (no large vacuum pump to wire, and no tubing runs to every location)

- Improves reliability since a pump issue affects only one point, and a spare unit can be swapped in

- Two channels (0.5 µm and 5.0 µm) commonly used for pharmaceutical applications

- Built-in buffer helps reduce missed samples

- Standard interfaces for easy integration: Ethernet and analog (4–20 mA)

- Optional Modbus over Ethernet driver available to support connectivity to your monitoring system

- System health indicators, including flow sensor and laser/detector health status

- VHP compatible for environments using vaporized hydrogen peroxide processes

Typical use cases:

- Pharmaceutical cleanrooms and controlled environments

- Facilities that want simpler installs and easier point-level serviceability

- Continuous monitoring programs where sample continuity is critical

High-Flow Particle Counters

High-flow particle counters are used for cleanroom certification, qualification, and investigative monitoring where larger air volumes are required.

Key characteristics:

- 28.3 LPM, 50 LPM, and 100 LPM flow options

- 0.3 µm and 0.5 µm particle size detection

- Supports cleanroom testing and validation activities

Typical use cases:

- Cleanroom qualification and requalification

- Performance verification

- Investigations and troubleshooting

Communication & Integration

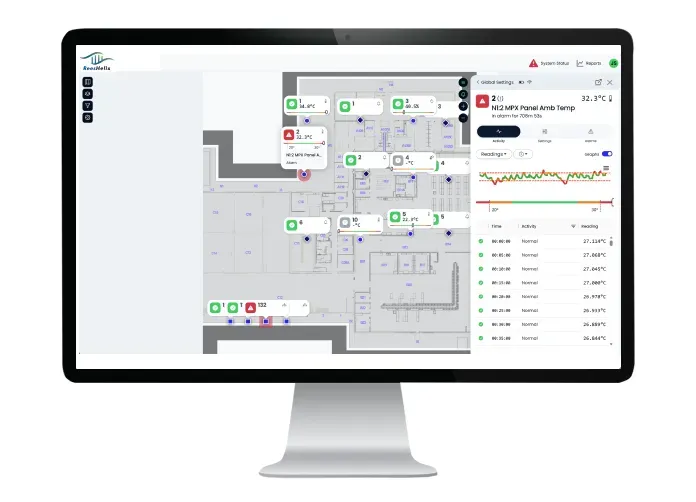

Particle counters can be integrated into the Rees Monitoring System to support centralized environmental oversight and electronic data collection. Continuous data capture, alarm management, and historical trending help teams document environmental performance and respond to excursions in a timely manner.

Integrated monitoring supports audit readiness by providing secure, time-stamped records aligned with electronic data integrity expectations.

Accessories & Supporting Components

To support proper installation and operation, a range of accessories is available, including:

- Isokinetic probes for accurate sampling

- Probe stands and mounting hardware

- Zero count filters

- Tubing and fittings

- Power supplies and regional power cords

- Transit cases for portable and validation use

These components help ensure accurate sampling and reliable long-term performance.

Designed to Fit Your Environment

Every controlled environment is different. Particle counter selection depends on factors such as room classification, airflow patterns, monitoring strategy, and system integration. Choosing the right configuration helps ensure particle data accurately reflects conditions in the space being monitored.

Talk to an Expert

Whether supporting cleanroom classification, ongoing environmental monitoring, or investigative testing, our team works with customers to translate monitoring requirements into practical solutions. We help align particle counter selection with both operational goals and regulatory expectations.