EMS

Hospital Refrigeration Temperature Monitoring Guide

Author: Gagan Kaur

Aug 19, 2025

Overview of Hospital Refrigerator Temperature Monitoring Systems

From blood banks to pharmacies, hospitals rely on refrigerators and freezers to safely store life-saving materials such as vaccines, medications, blood products, tissue samples, reagents, and more. But just having a medical-grade unit isn’t enough. What ensures compliance and patient safety is knowing the exact temperature inside that unit at all times. That’s where a hospital refrigeration temperature monitoring system comes in.

In this guide, we’ll walk through what these systems do, why they’re needed, and how to select the right approach for your facility.

Why Temperature Monitoring Matters in Healthcare Settings

Temperature excursions, even brief ones, can compromise the safety or effectiveness of stored materials. And in a healthcare setting, that can translate into patient risk, wasted inventory, or failed inspections. That’s why major regulatory agencies and accrediting bodies have clear requirements for continuous temperature monitoring, alarms, documentation, and validation. A proper refrigerator monitoring system can protect both the patients in your care and your facility against failed inspections.

Common examples of where temperature monitoring is required in hospitals:

- Pharmacy refrigeration (2°C to 8°C): For vaccines, insulin, antibiotics.

- Blood bank storage (1°C to 6°C for whole blood; frozen components require sub-zero).

- Lab and pathology storage: Tissues, reagents, and samples with temperature sensitivity.

- Operating room refrigerators: Anesthetics and certain surgical materials.

- Nutrition and dietary services: Specialized formulas and supplements.

What Are the Temperature Monitoring Requirements for a Hospital?

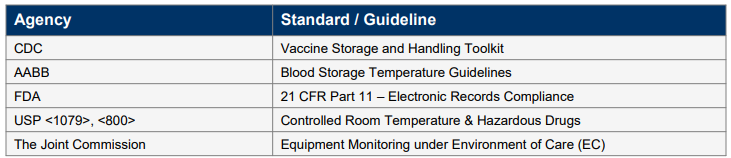

While specific requirements vary depending on application and region, most hospitals follow a mix of these standards:

Core requirements often include:

- Continuous Monitoring (not just daily min/max checks)

- Out-of-range Alerts (visual, audible, and remote)

- Automatic Data Logging

- Secure, tamper-proof records

- Annual calibration and validation

- Backup power and failover for critical systems

How Hospital Refrigerator Monitoring Systems Work

A typical hospital-grade temperature monitoring system consists of:

- Sensors: Calibrated probes placed inside refrigerators and freezers.

- Transmitters: Wired or wireless devices that send readings.

- Software: A platform that displays data in real time, logs trends, and sends alerts.

- Alarming: Multi-tier alerts that notify staff via email, text, or calls when thresholds are breached.

- Reporting: Downloadable audit trails, daily summaries, and temperature logs.

Advanced systems also offer:

- Network failover and cloud redundancy

- Access control and audit trails

- Integration with Building Management Systems (BMS)

- 21 CFR Part 11 compliance features

Refrigerator and Freezer Validation in Healthcare: Why It’s Non-Negotiable

Hospital refrigerators and freezers used to store critical materials must also be validated to confirm they operate correctly, consistently, and in line with regulatory expectations.

Validation isn’t just a box to check. It ensures that equipment performs reliably in real-world conditions, not just when it's new or freshly calibrated.

Validation typically includes:

- Installation Qualification (IQ) – Verifies the unit was installed according to manufacturer specs and hospital standards.

- Operational Qualification (OQ) – Confirms the unit functions properly within the expected ranges.

- Performance Qualification (PQ) – Proves the unit maintains those ranges under daily use.

When validation is required:

- During initial installation of a new unit

- After repairs or relocation

- When repurposing equipment for different storage needs (e.g., adding vaccines)

- As part of annual requalification and temperature mapping

Whether it’s a -20°C freezer for plasma or a 2–8°C refrigerator for medications and vaccines, validation gives facilities confidence that the equipment is safe, compliant, and audit-ready.

Choosing the Right System for Your Hospital

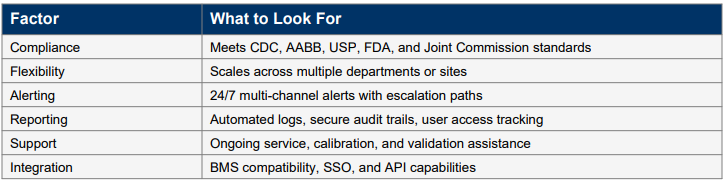

Not all systems are created equal. When evaluating a hospital refrigerator monitoring solution, consider:

FAQs

What are the temperature monitoring requirements for hospital refrigerators?

Hospitals must continuously monitor the temperature of refrigerators storing medications, vaccines, blood products, and lab materials. Most guidelines call for electronic monitoring with alerting, data logging, and annual calibration. Standards from the CDC, AABB, USP, and The Joint Commission typically apply.

How often should hospital refrigerator monitoring systems be calibrated?

Calibration is usually required annually, but some facilities choose to do it more frequently depending on audit schedules or internal quality procedures. It must be traceable to NIST standards.

Do hospitals need to validate their refrigerator monitoring systems?

Yes. Validation is important for systems used in pharmacy, blood bank, and clinical applications , especially if the data supports regulatory compliance. Validation typically includes IQ/OQ/PQ and should be documented.

Can I use a standard data logger instead of a full monitoring system?

For short-term monitoring, data loggers might be acceptable. But for long-term hospital use, you’ll likely need a validated system that provides continuous monitoring, alerts, audit trails, and secure record-keeping.

What happens if a hospital refrigerator fails overnight?

Without a monitoring system in place, a temperature excursion could go unnoticed, putting patient safety and compliance at risk. Systems with alerting and backup power help mitigate this risk by notifying staff immediately.

Final Thoughts

Temperature monitoring in hospitals is more than a compliance task, it’s a safeguard for patient care. Whether it’s a single vaccine fridge or a facility-wide monitoring system, accuracy and reliability matter.

Many hospitals today are moving beyond manual logs or fragmented systems and investing in centralized, validated, and integrated platforms. The result? Fewer risks, smoother audits, and greater confidence in cold storage management.

Rees Scientific

Hospitals across the globe use Rees Monitoring Systems to monitor critical storage across departments, from blood banks and pharmacies to ORs and labs. We provide 24/7 support, validation services, and systems designed to meet regulatory standards.

Contact our team to schedule a temperature monitoring assessment on your hospital’s system today.